The German Elon of the 70s

Meet Lutz Kayser, the pioneering rocket engineer and founder of OTRAG (Source: OTRAG)

It’s 1977 and you’re standing on a rocky plateau overlooking the dense jungle of Zaire in what is now modern-day Congo. You and a group of maverick engineers work for OTRAG, a West German rocket startup that is sponsored by Zaire’s dictator, Mobutu Sese Seko. After many months of toil in the African bushland, you’re ready to launch the world’s first privately developed rocket booster––a 9-meter (30 ft) tall juggernaut which, from a distance, looks like a bundle of aluminum pencils with a nose cone. The countdown proceeds smoothly. Then finally, there’s liftoff: the rocket leaves the launch pad with a deafening roar and climbs to an altitude of 12 km (7.5 miles) before plummeting back to Earth. The plateau erupts in jubilation.

Wait, what? This unlikely scene from the jungle might sound crazy to you. A private rocket company from West Germany that is attempting to make it into space in the late seventies? That’s more than three decades before Elon Musk’s SpaceX successfully launched its first rocket, the Falcon 1, into orbit! But this incredible and long-forgotten tale is entirely true and forms the plot of the documentary Fly Rocket Fly, which premiered at the Munich Film Festival in 2018. The film is now available to stream on Amazon Prime and Vimeo.

The rise and fall of OTRAG is one of the strangest, and most remarkable, startup tales I’ve encountered to date. It’s an almost surreal story of entrepreneurial adventure and ambition that bears an astonishing resemblance to Werner Herzog’s Fitzcarraldo. In Herzog’s 1982 movie, Klaus Kinski plays an obsessive dreamer who manually drags his massive steamship over a steep hill in the Amazon jungle. Unfortunately for Fitzcarraldo, this astonishing engineering feat doesn’t translate into his mission’s overall success (Herzog later went so far as to call it a “conquest of the useless”). The same could be said about OTRAG. Despite a number of successful test launches, OTRAG was a spectacular failure. The company burned through massive amounts of funding and eventually ran afoul of Cold War politics. Its demise is a case study in what happens to startups when their timing is wrong, their technology speculative, and their market unwilling to embrace disruptive innovation.

The Emperor of OTRAG

All startups are a reflection of their founders. The man behind the rocket-building adventure in the jungle was Lutz Kayser, a German aerospace engineer who was something of a 20th-century Elon Musk. Kayser began pursuing his dream of a low-cost rocket launcher in the 1960s. As a student of rocket pioneer Eugen Sänger, he experimented with new propulsion systems using industrially available components and low-cost fuels. The initial work with Sänger carried over into Kayser’s first startup, Technology Research Ltd., which he founded in 1970. The company received several million Deutschmark in research grants and was hired by the West German government to explore a low-cost alternative to the ailing Europa II rocket program.

It was during this time that Kayser developed his vision for a low-cost, modular rocket system that could transport satellites into orbit. The idea was as simple as it was revolutionary: it involved the parallel clustering of many standard fuel tank and engine modules (Bündelrakete). The smallest flight-worthy rocket module consisted of four clustered tank units and four identical engines. Bigger, more powerful boosters could be constructed by bundling together larger quantities of these tank-and-engine modules. The largest configuration on paper had as many as 600 individual engines! And there was another idiosyncrasy to the design: instead of being stacked atop one another, the stages would be nested inside one another and shed like layers of an onion as they burned out. This arrangement didn’t make for a particularly handsome vehicle and the rocket’s design was frequently compared to a bundle of asparagus. But aesthetics weren’t the point; “low cost, not high tech” was the North Star.

Lutz Kayser with a prototype of his “cluster rocket” (left), next to a design sketch by Klaus Bürgle (right). Source: OTRAG

The key to holding down the rocket’s cost lay in three simple design principles, some of which have been rediscovered by the current crop of “NewSpace” companies. The first principle was rooted in the modular platform architecture itself. Building a whole family of launch vehicles around the same tank-and-engine modules simplified the vehicle configuration and saved millions in development costs. It also meant lots of tanks and engines in production, generating both economies of scale and lower prices. SpaceX applies the same design philosophy today: its main rocket, the Falcon 9, employs nine identical engines (plus another one to power the second stage), while the Falcon Heavy uses 27 units of the same engine. This creates a virtuous cycle whereby the operating model helps drive the business model: being the cheapest launch provider in the market translates into a greater number of launch contracts, which in turn drives higher volumes and scale efficiencies. Once this flywheel is in motion, it becomes easier to run the business as it continues to operate.

The second design principle was to use mass produced, commercially available components instead of expensive “space grade” equipment from government contractors. The tank units, for example, were made of long pipeline tubes that were manufactured by the German steelmaker Krupp. Amusingly, a Volkswagen windshield-wiper motor was used to open and close the valves that controlled the propellant flow to the engines. Complex and trouble-prone components, like turbopumps or gimbals, were avoided altogether. Instead, the fuel tanks were partially filled with compressed air that forced the propellant into the engines, and the rocket was steered by throttling back individual engines on the side where less thrust was desired. SpaceX would later use components from existing supply chains as well: The Falcon 1 used readily available car wash valves with modified seals to feed propellant into the engine, while the first Dragon spacecraft utilized a modified bathroom stall latch for securing the cargo lockers.

The third design principle was a simplified rocket engine that could run on extremely low-cost fuels. The basic job of rocket fuel is to burn steadily and intensely when combined with an oxidizer. Once the fuel and oxidizer are fed through an injector into the combustion chamber, they produce a hot gas that shoots out of the bell-shaped exhaust nozzle at the bottom. This creates the necessary thrust to launch the rocket upwards. The most common rocket propellant in use today is a mix of ultra-refined kerosene (RP-1) and liquid oxygen (LOX). SpaceX, Rocket Lab, and many other launch providers work with this fuel mix. Kayser, in contrast, opted for a much cheaper propellant combination: regular diesel oil as fuel and nitric acid as oxidizer. Though providing less thrust per pound than RP-1/LOX and being extremely toxic, this combination cost only 5% as much and was readily available.

Kayser in the control center at the German Aerospace Center in Lampoldshausen. Source: OTRAG

Much of the early work on this novel rocket concept was done at a test stand rented from the German Aerospace Center in Lampoldshausen, north of Stuttgart. Over a period of four years, Kayser’s team went through hundreds of test firings to perfect the diesel oil/nitric acid cocktail. The biggest challenge around getting the engine to work was the “hypergolic” nature of the fuel mix: diesel oil and nitric acid ignite immediately upon contact and are subject to unstable burning. Just getting the engine started was difficult: if ignition happened too late, a pool of almost-ready to burn propellant had already accumulated in the combustion chamber, triggering an explosion that would demolish the engine and its immediate surroundings. The group eventually achieved a breakthrough by inventing a radial fuel injection system that provided the right vapor mixture of fuel and oxidizer.

Then came an unexpected setback. By 1974, the West German government had lost interest in the project and decided to concentrate its rocket research efforts on a new, pan-European launch vehicle, the Ariane 1. Technology Research Ltd.’s fiscal tap was shut off. Kayser was undeterred. He began looking for private funding to bring his rocket to market but it was difficult. Venture capital as we know it today didn’t exist in 1974. Venerable firms like Kleiner Perkins and Sequoia, both founded in 1972, were still in their infancy and unavailable to a little-known entrepreneur from West Germany. Kayser’s only option was a highly unorthodox crowdfunding strategy: he decided to raise money from wealthy individuals who wrote off their investment through tax deductions (Abschreibungsgesellschaft). Few investors believed that Kayser’s company would actually succeed, but that didn’t matter; a tax loophole allowed investors to deduct up to 275% of the invested capital from taxable gains made elsewhere. Unorthodox as it was, it allowed Kayser to raise what must be the biggest angel round in history: 1,500 individuals––dentists, lawyers, and the like––committed 173 million D-Mark to Kayser’s new company (the inflation-adjusted equivalent of more than $400 million today).

Thus was born the world’s first private space company, OTRAG, which Kayser incorporated in 1975. The name was an acronym that translated to Orbital Transport and Rockets, Inc. Kayser’s business plan was to become the “Southwest Airlines of Space” by offering significantly lower prices and targeting customers with underserved needs, such as Third World governments and commercial satellite providers. “What we want to do is bring launching costs down to a commercially sensible ratio to satellite costs,” Kayser told the journalist John Dornberg. “As satellites themselves get progressively cheaper, it will be like transporting bags of cement in a Rolls-Royce. To carry cement you ought to use a truck, and that’s what we are building––a space truck.” To bolster his credibility, he recruited Kurt Debus, the former director of NASA’s Kennedy Space Center and a long-time associate of Wernher von Braun, as chairman of the board. The space community remained doubtful, though, and joked that “asparagus can’t fly.”

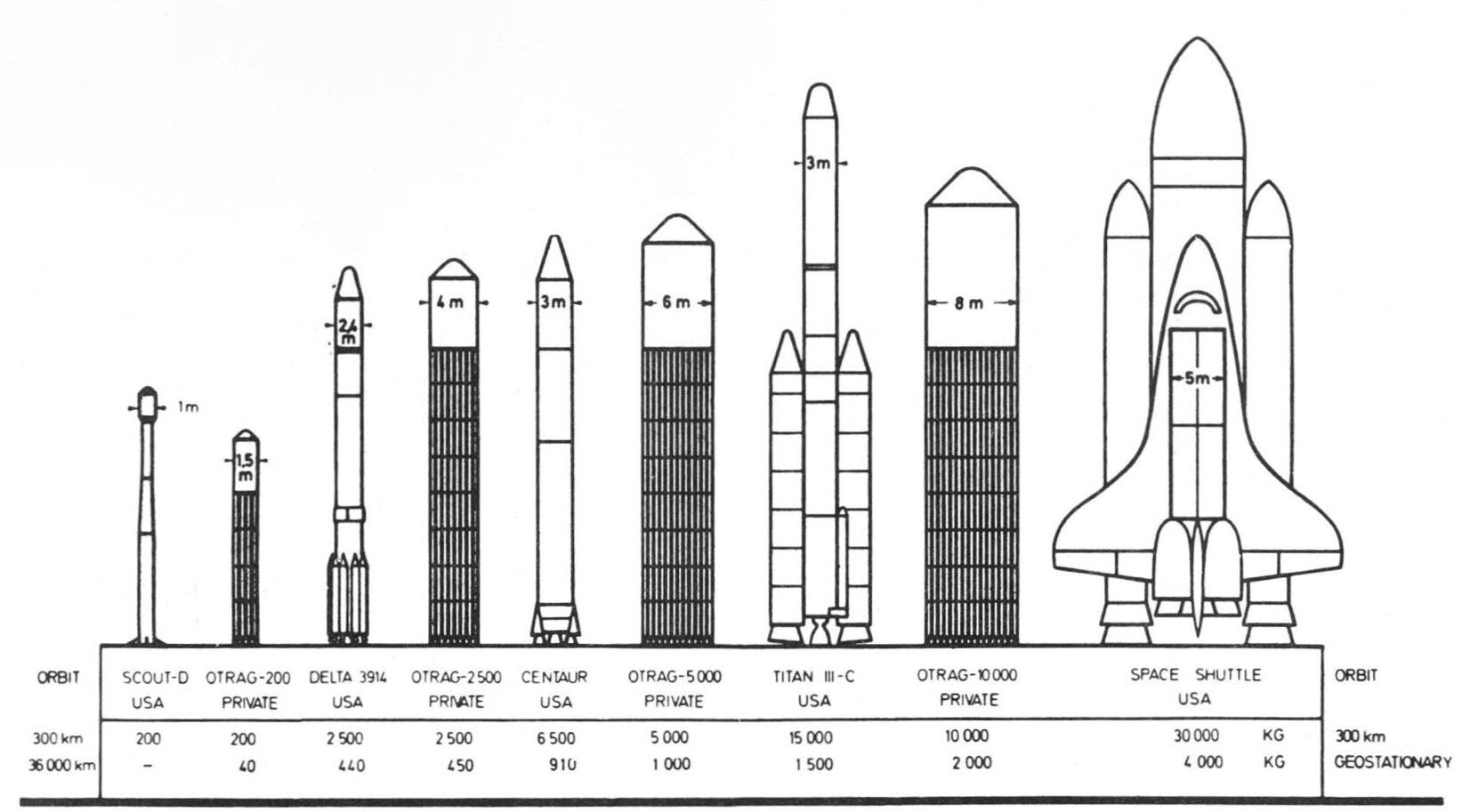

OTRAG’s rocket in different configurations, compared to US launchers of the 1970s. Source: Popular Science 1978

The company had another major hurdle to overcome: the 1954 Treaty of Brussels prohibited the launch of long-range missiles on German territory. Kayser began looking for a large, sparsely populated launch site along the equator where the earth’s spin would make it easier to place rockets into orbit. He negotiated with several countries, including Brazil and Indonesia, before eventually settling on a country that could hardly be called politically stable: the Republic of Zaire. In a stunning deal with Zaire’s dictator Mobutu, OTRAG received the exclusive right to lease a vast area of 100,000 km2 (38,000 mi2) for up to 25 years. The territory, on the plateau of Shaba, was roughly the size of the former East Germany (!) and rent-free until the firm became profitable. Zaire’s neighbors immediately rose in an angry chorus, criticizing the deal as a new act of colonization. Their protests were echoed by the Soviet Union, which circulated the unsubstantiated claim that West Germany was using OTRAG as a cover to develop military missiles in Africa.

Kayser ignored these obvious warning signs and began flying equipment down to Zaire. Within months, his team had set up a private spaceport in the Congolese jungle, including a provisional launch pad, control bunkers, and a housing facility. One of the engineers, Victor Löbermann, later recounted: “My first thought was, wow, these guys are completely nuts. The whole idea of launching rockets in the African jungle was just surreal. But I got hooked over time.” In May 1977, OTRAG was finally ready for the first public demonstration of its minimum viable product––a single-stage rocket booster with four engines. Though its tanks were filled to only 20% capacity, the maiden flight to low altitudes caused a global media sensation. If there was any remaining doubt that Kayser’s Spargel could fly, it was laid to rest by the company’s next launch in March 1978. The second rocket, identical to the first but with full tanks, soared to an altitude of 30 km (18.5 miles) before the engines shut down. At the press conference following the launch, Kayser told journalists that OTRAG would become fully operational by 1981 and operate ten commercial launches per year. He also announced that the company’s biggest launcher would be sold at half the price of NASA’s Space Shuttle or ESA’s Ariane 1. What could go wrong now?

The company’s MVP, the OTRAG-1 (left). Two OTRAG employees assemble a tank unit (right). Source: OTRAG

As it turned out, a lot. The two superpowers became increasingly concerned about the implications of a private company launching espionage satellites into orbit. France––the largest stakeholder in the Ariane rocket program––was also worried. With the Cold War in full swing, OTRAG found itself in the crossfire between Washington, Moscow and Paris. More bad news arrived in June 1978 when Mobutu visited the launch site with a large press corps in tow. They came to witness OTRAG’s third test flight, but ended up witnessing a disaster: Immediately after liftoff, the rocket turned rapidly to the left and crashed into the Luvua River a few kilometers away. It was an all too painful reminder that in rocketry the margin of error is incredibly small. Worse still, the media footage made it look like OTRAG was launching a cruise missile instead of a benevolent space truck. The situation quickly escalated into a political firestorm. Under pressure from the Soviet Union and France, Mobutu canceled the launch site pact with OTRAG and asked the company to close down its facilities in Zaire until the end of the year.

So by 1979, Kayser once again found himself on the lookout for a launch site. After unsuccessful talks with Brazil and France, he quietly relocated the launch facilities to the Sahara desert in Libya. Kayser’s decision to associate himself with Colonel Muammar Gaddafi was sobering evidence that he was willing to make yet another Faustian bargain with an African dictator. The Islamic connection to Libya was the straw to break the camel’s back. OTRAG’s board promptly fired Kayser and appointed Frank Wukasch as CEO. The company launched several more rockets from Libya but continued to be in the news for all the wrong reasons. In the mid-1980s, the German Fiscal Court (Bundesfinanzhof) began investigating the company’s financial situation. The court concluded that OTRAG was a gigantic tax fiddle and closed the tax loophole that had attracted investors. Without new funding or public support, OTRAG had run out of options. It shut down in 1987 and was soon to be forgotten, a tiny dot in the rear view mirror of a world shuttling ahead. Kayser passed away in 2017, shortly after the documentary was completed.

Kayser on Bikendrik Island, a tiny island in the Pacific where he lived until his death in 2017. Source: OTRAG

OTRAG’s legacy

If there’s one thing the OTRAG saga teaches us, it’s that startup success is as much about timing as having the right vision: Enter too early and the market isn’t ready for you. Enter too late and you fight an uphill battle against incumbents. Unfortunately for the entrepreneur, timing is often difficult to identify and to control. Take two of Silicon Valley’s most prominent failures, GO Corp and General Magic, both of which tried to bring a tablet computer to market in the early 1990s. Although the concept proved visionary, their timing and execution did not. After burning through funding of $75 million and $200 million respectively, both flamed out without ever launching a marketable product. “It’s like surfing,” Jerry Kaplan later wrote about the failure of GO. “There can be lots of people out there on their boards. But you have to be at just the right spot to catch the wave at the very top.”

Lutz Kayser was the first to spot the potential of private spaceflight, but it was long before the wave was ready to crest. It was the right idea at the wrong time. More troubling, he had no qualms about collaborating with African dictators and stepping into a minefield of Cold War politics by challenging the US-USSR monopoly on spy satellites. Kayser’s wilful naivety could be described as baffling, but it’s actually not that uncommon in the startup world. Elon Musk is proof that successful entrepreneurs don’t function entirely on rationality: No rational person invests his entire fortune to take on the space and the auto industry at the same time. Marc Porat, the former CEO of General Magic, provides the following explanation: “You need an enormous amount of momentum and that momentum comes from suppressing introspection about the possibility of failure.” There are limits, though: It’s when irrationality and naivety coincide with a complete lack of judgement that things are bound to fall apart.

OTRAG was doomed for other reasons as well. For one thing, the technology was extremely speculative. Kayser’s design principles were remarkably prescient in hindsight, but his execution didn’t do them justice. Most problematic was the rocket’s weight, which stemmed from its unconventional architecture and the low thrust-to-weight ratio of the fuels. The launch vehicle would have been twice as heavy as conventional rockets for the same payload capacity, and exceptionally difficult to steer. Good luck building a guidance system that can automatically throttle hundreds of individual engines––all with 70s hardware and without the limitless coffers of NASA.

Moreover, Kayser’s idea hit a market that wasn’t yet ready to embrace commercial rocket development. To quote Jason Calacanis, “It’s not who gets there first. It’s who gets there first when the market is ready.” Kayser boldly bet on the thesis that a drastic reduction in space launch cost would create a large market for commercial payloads. But this was unlikely to have happened even if the technology and the politics had played out. The major satellite fleet operators that drive demand today didn’t exist yet in the 1970s. For example, the European satellite giant SES, which today is one of SpaceX’s most important commercial customers, wasn’t founded until 1985, and it took another three decades before tech companies like Facebook or Amazon would begin launching internet satellites of their own. Kayser admits in the documentary that “you can lead a horse to water but you can’t make it drink. If the market isn’t desperate for low-cost access to space, then there’s simply no market yet.”

SpaceX’s timing proved more fortuitous because it coincided with steadily rising launch prices and reduced options in the rocket world. This made buyers, including NASA, more willing to invest in an untried commercial system that could reduce the cost of launching humans and cargo into space. In addition, the early 2000s saw a cultural and institutional transformation within government space programs. In 2006, NASA decided to move away from its conventional “cost-plus” procurement, which guaranteed contractors a profit on top of the costs they accrued. Instead, the agency began awarding fixed-price contracts to a competing set of launch providers. This shifted risk from NASA to private companies and turned the agency from an overseer of private contractors into a patron and anchor customer for “NewSpace” startups. It’s hard to overstate the importance of this procurement shake-up in the ultimate success of SpaceX. After all, it was NASA’s “Christmas present”––a $1.6 billion contract for missions to resupply the ISS––that saved SpaceX from bankruptcy in 2008.

That is not to say that Elon Musk doesn’t deserve full credit for succeeding where Lutz Kayser failed. No one has summarized his contributions more eloquently than the renown Mars visionary Robert Zubrin:

“Unlike the other would-be space magnates, Musk did not simply throw an expendable chunk of his fortune into the game; he put the full force of his talent and passion into it. When I met Musk in 2001, he had a good grasp of scientific principles, but knew nothing about rocket engines. When I visited him at his first small factory in Los Angeles in 2005, he knew everything about rocket engines. By the time of my next visit a few years later, he had experienced two straight failures of his first launch vehicle, the Falcon 1, but was determined to push on despite the blows to his finances and reputation. It is this level of commitment that has made all the difference.”

History is written by the victors, so it’s hardly surprising that OTRAG disappeared into oblivion. But Lutz Kayser deserves a place in history. He paved the way for the now burgeoning space economy by being the first to rethink the calculus for rocket companies. Moreover, his crazy adventure is a reminder that Germany once played an early leadership role in commercial rocketry and other deep tech areas, like self-driving cars (see Ernst Dickmanns in the 1980s). Although Germany is now set to rejoin the commercial space race with Isar Aerospace, the Munich-based company can hardly be called a “zero-to-one” startup like OTRAG. There are now over 100 commercial launch providers in the world and not enough demand for all of them. Experts see the market shaking out to no more than ten companies. SpaceX President Gwynne Shotwell goes even further by saying that she doesn’t think “there is enough room for more than two, maybe three of these micro launchers”. There’s a sliver of hope, though: in a world that is increasingly fragmented at every level, Isar Aerospace could still succeed as a “geopolitical play” that gives Europe an independent, low-cost gateway to space. If that happens, it would close the circle that Kayser started half a century ago: his nephew Lin Kayser sits on the board of Isar Aerospace.